A legacy forged on the waterfront of Tokyo Bay

For more than a century, Japan’s steel industry has been shaped by a culture of precision, discipline, and relentless innovation. Few places embody this legacy more powerfully than Kawasaki, the industrial city that became home to Nippon Kokan (NKK) and later JFE Steel’s Keihin district. Rising from the man‑made island of Ogishima, the Keihin complex remains as a symbol of Japan’s industrial ambition — an engineered island dedicated to the art of steelmaking.

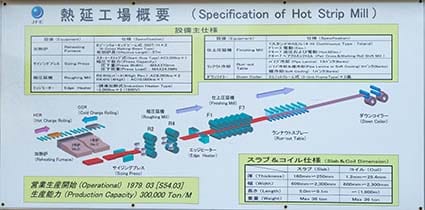

Here, in a region where Japan first merged heavy industry with modern urban life, JFE built one of the country’s most advanced steelmaking complexes. At it’s heart stood the Keihin Hot Strip Mill, commissioned in 1979 and continuously modernized to remain at the forefront of global steel production.

The mill was constructed using technology from Japan’s most respected heavy‑industry manufacturers: Mitsubishi, Hitachi, and IHI. These companies are synonymous with advanced engineering, robust mechanical design, and exceptional long‑term reliability. Their contribution ensured decades of stable operation, tight tolerances, and consistent product quality.

Engineering excellence: Japan’s widest Hot‑Rolled Strip

The Keihin HSM was designed to push boundaries. It’s capabilities remain impressive even by today’s global standards:

- Rolling width: up to 2,300 mm, among the widest in Japan

- Slab thickness: 160–250 mm

- Strip thickness: 1.2–25.4 mm

- Annual capacity: approx. 4,000,000 tons

- Product range: from ultra‑thin automotive sheet to heavy‑gauge line‑pipe material

- Rolling stands: two roughing and seven finishing stands

- Core technology: Pair Cross Shift Mill for advanced shape control

- Major upgrade (2009): Sizing Press enabling variable strip widths from constant‑width slabs

- Major upgrade (2013): installation of a 3rd downcoiler, increasing coiling flexibility, improving product flow, and boosting overall throughput

The mill features the world’s first Pair Cross Shift Mill, a breakthrough technology that dramatically improved strip shape control. Combined with JFE’s advanced cooling‑control systems, the line was able to produce high‑strength, high‑workability steels that conventional mills could not achieve. These capabilities earned the Keihin HSM high praise from automotive manufacturers and other premium customers, reinforcing it’s reputation as one of Japan’s most advanced rolling lines.

The addition of the Sizing Press was transformative. It increased upstream caster productivity, reduced slab inventory complexity, and expanded the mill’s product envelope — allowing JFE to respond quickly to the evolving needs of automotive, energy, and infrastructure customers.

This was a mill built for flexibility, efficiency, and high‑volume output.

A mill that grew with Japan’s industrial ambition

From the 1980s through the 2020s, the Keihin HSM supplied steel to some of Japan’s most demanding sectors:

- Automotive OEMs requiring thin, high‑strength sheet

- Pipeline and energy companies needing robust, wide‑gauge strip

- Construction and machinery manufacturers relying on consistent, defect‑free coil

It’s production supported Japan’s rise as a global manufacturing powerhouse. It’s innovations influenced hot strip mill design worldwide.

Even as the mill approached its final years, JFE continued to invest — reflecting the company’s belief in the mill’s strategic importance and the enduring value of it’s technology.

Production ceased in September 2023, not due to obsolescence, but as part of a broader structural consolidation in Japan’s steel industry. The mill’s legacy remains intact: a high‑capacity rolling mill with decades of remaining potential.

A rare opportunity: A Japanese‑engineered HSM on the global market

Today, Hilco is proud to present this exceptional asset to the international market.

The Keihin Hot Strip Mill is a complete, proven, high‑performance rolling mill built on:

- Japanese engineering discipline and robust machinery

- Continuous modernization

- A culture of precision and reliability

- A track record of producing premium steel for the most demanding applications

For buyers seeking to expand rolling capacity, upgrade existing operations, or establish a new benchmark facility, the Keihin HSM represents a once‑in‑a‑generation acquisition.

It’s story is one of innovation, resilience, and excellence. Its future now awaits a new chapter — one that a new owner can write.