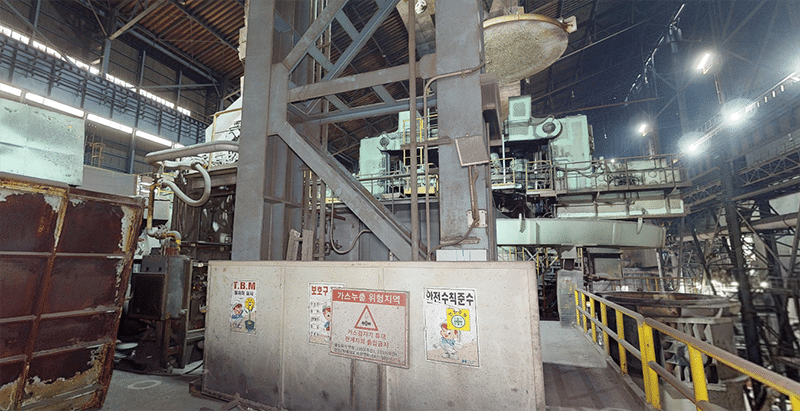

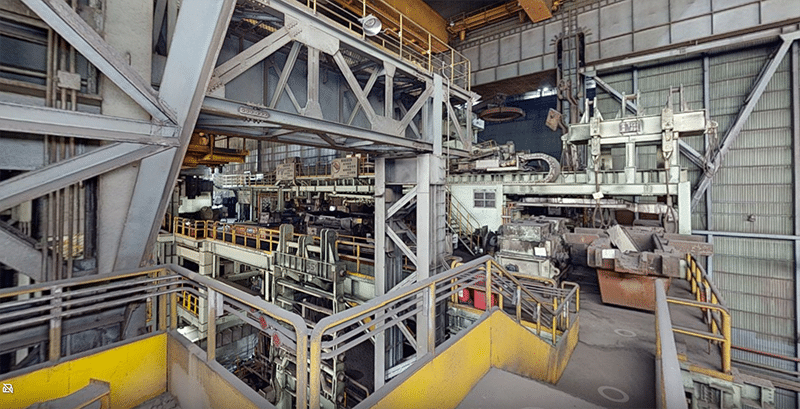

Hyundai Steel Dangjin Facility (widely known as “Thin Plate Mill”) is a premier steel production plant featuring a Compact Strip Process (CSP) as the main production line, complemented by a 150-tonne heat-size electric Meltshop, a thick Slab Caster, and a Skin Pass Mill.

Initially commissioned by Hanbo Steel in 1995, this facility was acquired by Hyundai Steel in 2004 including a major modernization in 2011 and more recent upgrades, ensuring its continued excellence in production.

Assets Available for Sale:

• Electric Meltshop 150 tonnes heat size – DC EBT Electric Arc Furnace, Ladle Furnace, Vacuum Degasser and associated equipment.

• CSP – A Thin Slab Cast & Rolling line combining casting, heating, and rolling. 55mm thickness slabs directly enter a tunnel furnace and are rolled in a Hot Strip Mill for final strip thickness from 1.4 to 16mm and up to 1,560mm width. While operating with one out of two single-strand twin casters, 1.0 million tons Hot strip per year can be produced. The second caster along with the furnace adds flexibility and nearly doubles the production capacity.

• Skin Pass Mill capable of handling widths up to 1,600mm and thicknesses from 1.2 to 6. incl. up-to-date measuring equipment.

• Thick Slab Caster – Vertical bending caster designed for the production of high-quality medium-to-thick slabs, with a thickness of 210mm and widths of 600–1,890mm.

Above lines are offered with an extensive list of overhead cranes, auxiliary machinery, consumables, operational and capital spares.