Set along Korea’s western coastline, the Dangjin Works sits within a landscape shaped by logistics, shipbuilding, and coastal industry. It is a place where the country’s manufacturing capabilities took form, supported by the infrastructure that lines the Yellow Sea.

In the mid1990s, this site became home to a technology that reshaped the steel world: thin slab casting and rolling, or TSCR.

TSCR: a shift in how steel could be made

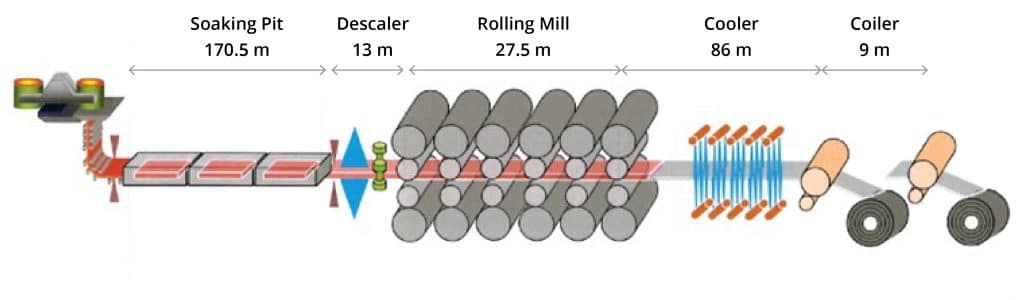

For decades, flatrolled steel production followed a predictable pattern: casting thick slabs, reheating, and rolling in energy-intensive mills. TSCR disrupted that logic by integrating casting and rolling into a single, continuous process. The idea was simple but transformative:

- less energy

- less footprint

- less capital cost

- a faster route from liquid steel to finished strip

The breakthrough that made TSCR possible came in 1985, when SMS cast the first 50mm thin slab in a pilot plant — a milestone that paved the way for CSP’s industrial debut in 1989. CSP became the first successful industrial application of TSCR, and over time the broader TSCR family expanded into several variants — CSP, ISP, ESP, QSP, DUE, etc. — each refining the concept in its own way.

The CSP line at Hyundai Steel Dangjin

- 1995 – Commissioned by Hanbo Steel, with the first coil produced in June as SMS Group’s fifth global CSP reference

- 2004 – HANBO was acquired by Hyundai Steel and the CSP Line was modernized for reliable, high‑quality production

- 2011 – Major revamp with new electrical and automation systems

- 2020 – Mothballed in June after 25 years of consistent operation

CSP and the opening of new markets

CSP — and TSCR more broadly — changed the competitive landscape of flatrolled steel:

- minimills could enter markets once dominated by integrated producers

- energy consumption dropped dramatically

- plant footprints shrank

- reduced capex and opex

Dangjin’s CSP line was part of this shift, demonstrating that thinslab technology could thrive in Korea’s demanding industrial environment and contribute to the country’s rapid industrial growth. Today, the line stands ready to be adapted to new contexts and to serve emerging markets.